|

Eliminating Vibration

In my engine re-build

description in the January Jaguar Driver I described how I achieved a

better balanced engine. In this article I'd like to raise the

questions of transmission and wheel balance.

It is well known that the Hardy-Spicer joints at the ends of the prop

shaft must be arranged so that they hinge in the same plane as each

other. The fact that our shafts have a splined section at the front

makes it possible for them to be wrongly aligned.

Another equally important alignment that often receives less attention

is the relationship between the gearbox output shaft and the rear axle

input shaft. The Hardy-Spicer joints are not constant velocity joints.

If you try rotating one with a large angle applied then you will see

that the output shaft leaps along through two parts of its rotation

only to slow down at the two parts in between.

See:http://en.wikipedia.org/wiki/Universal_joint

The degree to which the velocity changes is a function of the angle

applied to the joint. In the case of our prop shafts the input angle

must match the output angle. In other words the gearbox shaft must lie

in a parallel plane to the rear axle input shaft. If this condition is

not met then, whilst the rear wheels must rotate with a regular

constant velocity this will force the engine to rotate with varying

velocity which will be apparent as vibration. Looking at the factory

drawing of the side elevation you can see that the line of the rear

axle pinion is horizontal but the crankshaft/gearbox axis is slightly

canted downwards to the rear. This is strange as it suggests that they

were unaware of the need for these to be on parallel axes

.jpg)

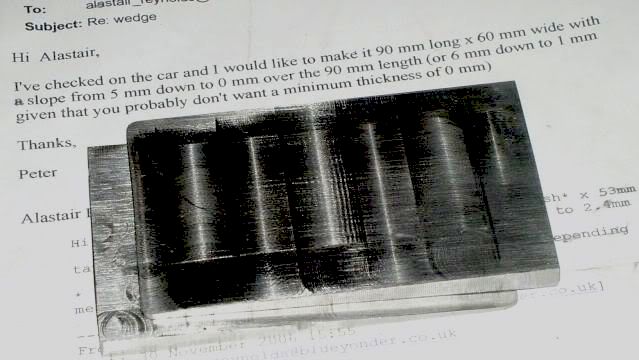

I have looked at quite a few cars and many, particularly pre-war ones,

are far from having parallel shafts. In my own car I needed to insert

steel wedges between the axle and rear springs. These have a

difference in height of about 5 mm if memory serves me correctly. The

effect of this modification was a dramatic improvement. Before you

suggest it, there was no evidence that the chassis was folding in the

middle.

We all know that wheels must be balanced. Unfortunately tyre fitters

rarely have the tools to mount our wheels in their dynamic balancing

machines. Fortunately they are usually happy to supply you with sticky

weights so that you can balance the wheels for yourself.

You need a freely rotating hub for this so it's necessary to remove

the rear wheels and balance them on the front axle. Unfortunately SS

and Jaguar do not appear to have balanced the brake drums. You could

take them to a machine shop and have them balanced but if you haven't

done this then you must balance your wheels along with the drums that

they will be mounted next to and you need to mark the relationship

between wheel and drum so that the wheel is always fitted with the

same angular position as you used when balancing them.

To minimise the quantity of sticky weights it's worth determining the

heavy points of the wheels and drums separately and then arrange the

wheel and drum points to be 180 degrees apart.

The act of balancing is just static balance. In other words let the

wheel or drum or combination rotate and note where it stops then apply

sticky weights to what is now the top point of the wheel. This is just

trial and error so you need to add weight progressively until the

wheel shows no particular tendency to always stop at the same point.

The weights can be applied to the relatively flat part of the wheel

behind where the spokes attach to the rim.

If you've followed this garbled description then hopefully you will

have a nice smooth running car that isn't wasting its energy trying to

vibrate everything.

|