|

A Comparison

between the SS Engine and the XK

I was reading William

Heynes' paper to the Institute of Mechanical Engineers on "The Jaguar

Engine" published 1953 and found one or two interesting comparisons

that put us in our place.

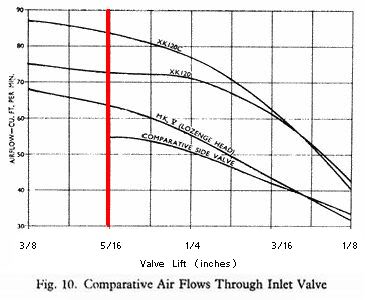

Firstly the XK head design apparently results in much simpler

machining and a very significant weight saving. The alloy XK head

weighs about 50 lbs but would have been 120 lb in cast iron.

Comparing the hemispherical combustion chambers of the XK with our

lozenge shaped chambers, or heart shaped for the side valve engines,

the XK gives a fairly obvious benefit in that the valves are not

socketed by the chamber and Heynes shows the increase in air flow rate

of the inlet valve for four types of engine. A side valve unit, a Mark

V, an XK120 and an XK120C. All four engines being of similar capacity.

Our cars have 5/16" valve lift and I've added a red line at this value

on the graph.

See also:

Jaguar and the Gas Meter

The results are:

Side Valve...55 cu ft/min

Mark V........64 cu ft/min

XK120.........72 cu ft/min

XK120C.......84 cu ft/min

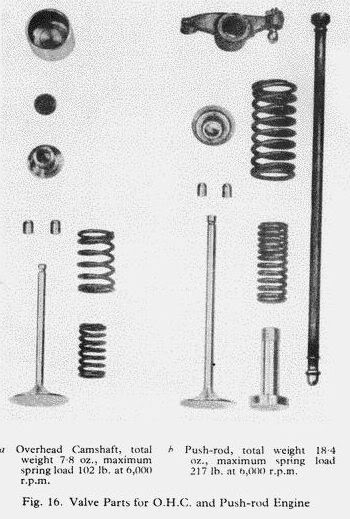

Apart from the big flow rate advantage Heynes describes how the OHC

arrangement of the XK removes the side loads on the valve stems that

are an unfortunate feature of using rockers as in our OHV engines and

causes stem wear and can lead to valve sticking.

The simplicity of the XK valve train gives a halving of the mass of

components when compared to our OHV engines. The SS components add up

to 18.4 ounces whereas this is reduced to a mere 7.8 ounces in the XK.

This significant reduction in mass permitted much lighter pressures to

be applied by the valve springs and whilst quoted at 6000rpm the

maximum spring load was reduced from 217 lbs down to 102 lbs in the XK.

Heynes points out that this reduced spring pressure gives significant

benefit in terms of valve seat wear and lessens the possiblity of

valve breakage.

Another design element that Haynes covers is the XK crankshaft. He

points out how the centre main bearing carries much larger stresses

than the intermediates and to address this they arranged the oil

passages so that the centre main is supplied from the oil gallery as

usual but it in turn is not required to pass on the oil to adjacent

big ends. This is not the case in our engines and it was certainly

true that the centre main in the last one I dismantled showed fatigue

failures not apparent in the intermediates.

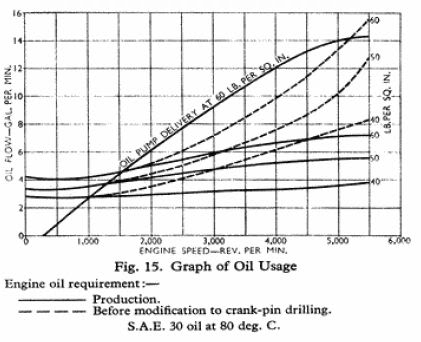

Haynes also shows an interesting graph of the flow rate provided by

the XK oil pump plotted against engine revs. but more interesting are

the plots of flow rate through the engine for crankshafts of the

original design and then for a design with modified oil passage

drilling. The original oil feed to the big ends exits at the point of

greatest radius of the crank and it throws the oil out of the big end

bearing due to centrifugal force. The effect of the centrifugal force

is reduced at smaller radii so the modified big end oil feed exits

through another drilling at right angles to the original drilling and

is thus positioned half a crank pin thickness less.

As you can see from the graph, even at moderate r.p.m. the modified

drilling significantly reduces the quantity of engine oil required to

maintain a given oil pressure.

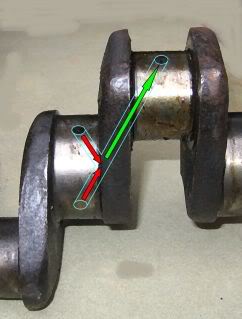

Unfortunately our crankshafts have their big end feeds at the point of

maximum radius. The picture below shows our shaft with oil being fed

(in red) in from a main bearing and how it is supplied (in green) to

the adjacent big end bearing at the point of maximum radius of the

crank.

Finally, a 4 cylinder comparison of the

SS 1½ litre engine with the

experimental XG engine that used a similar head design to the

BMW328. Apparently the valve gear proved to be rather noisy until they

fitted additional return springs on the exhaust pushrods. The XG

actually used the same block as the 1½

litre but the original head studs were not conveniently positioned for

the new head. For this experiment they had to reposition some studs to

places where they were simply screwed into the thin top deck without

the usual reinforcement.

N.B. The two sections are not taken at

the same location on the block, hence the apparent lack of an oil pump

in the XG.

.jpg)

|